- Home

- Infographics

- Shell and tube heat exchanger

Shell and tube heat exchanger

What is a shell and tube heat exchanger?

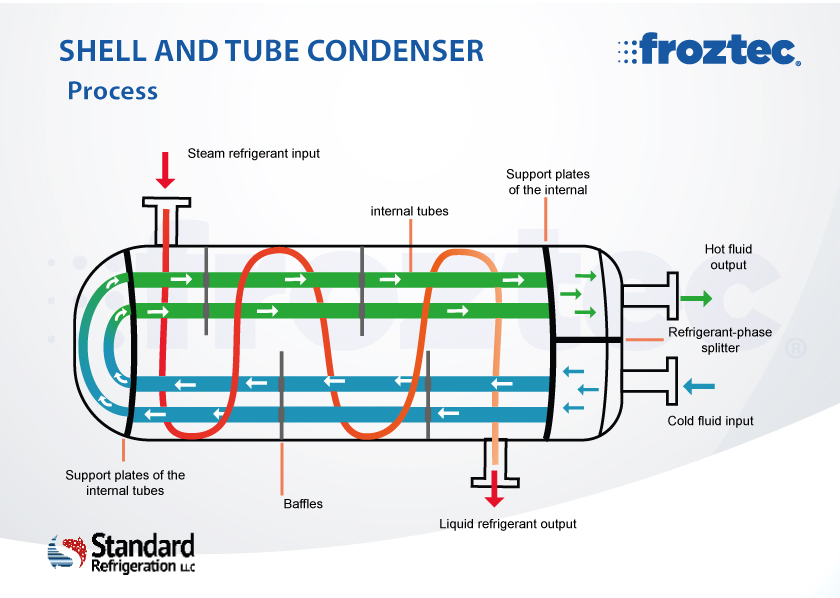

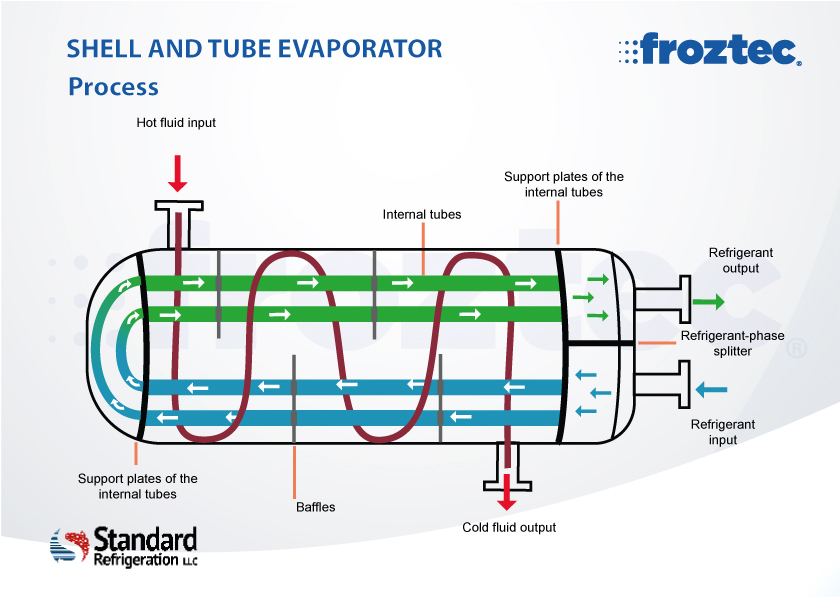

A shell and tube heat exchanger is engineered mainly to increase a fluid’s temperature by transferring heat from another with lower temperature. This equipment features an external shell that holds a circuit of smaller tubes. Heat is transferred, inside the heat exchanger, between the circulating fluid in the tubes and the fluid in the shell.

An effective heat exchange can only be achieved when there is sufficient difference in the heat levels produced inside the equipment: the higher this difference in temperature, the smaller will be the heat transference surface necessary during this process.

Design and operation

The parts of this type of equipment consist of a cylindrical shell housing a nest or bundle of tubes parallel to the longitudinal axis of the shell; the tubes can have fins or not and are fixed at each side by perforated plates. These tubes also feature a series of support plates called baffles across the shell that serve to perpendicularly direct at all times, the circulating fluid to the tubes, which will then be transferred via special pipes, known as ducts or floating heads.

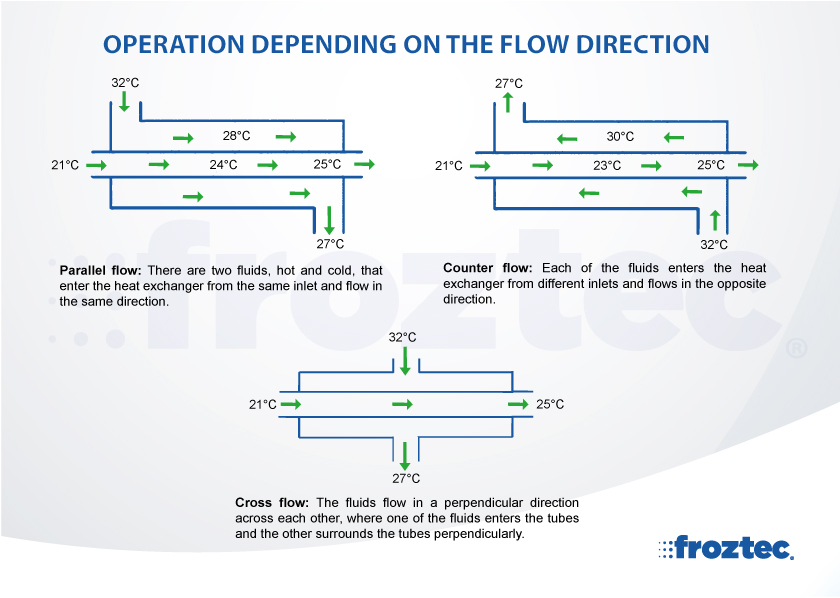

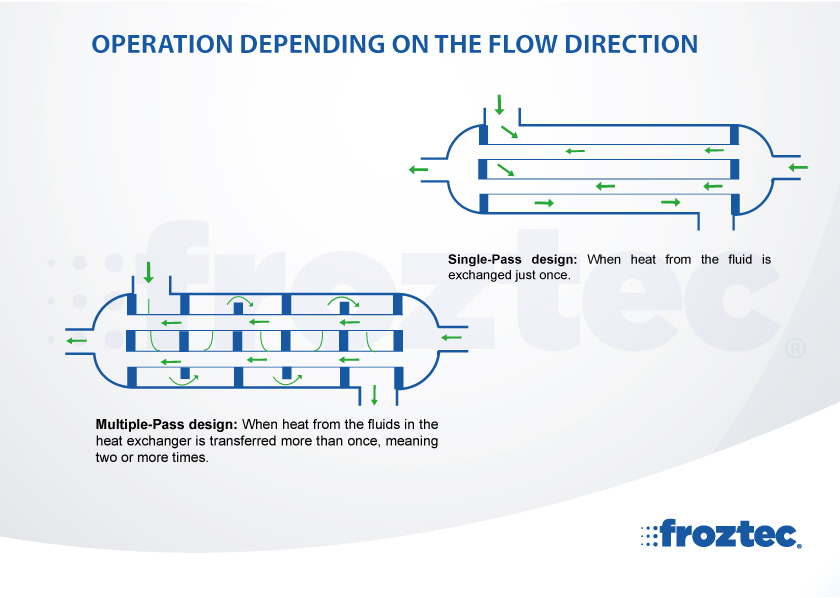

The operation type depends on the flow direction:

Parallel flow: There are two fluids, hot and cold, that enter the heat exchanger from the same inlet and flow in the same direction.

Basic information for a proper selection

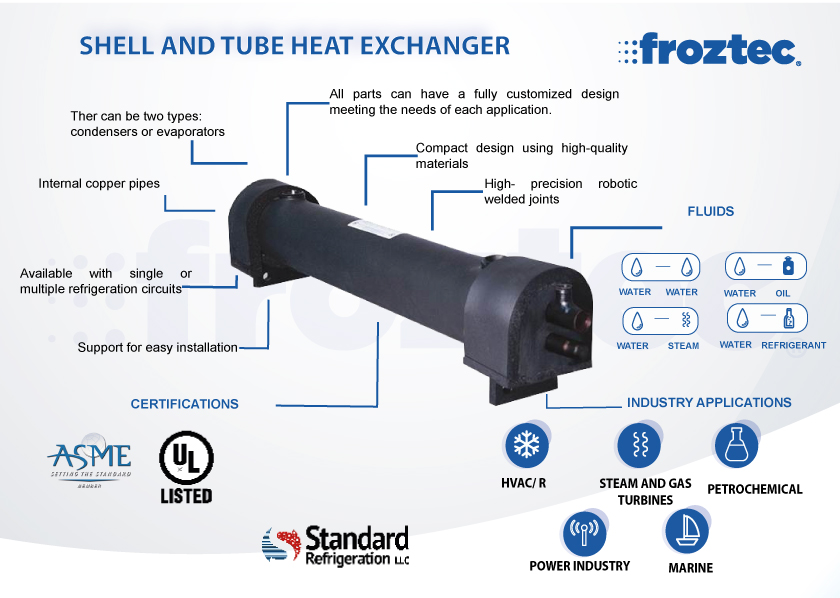

- Fluids (water / water, water / oil, water /steam, etc.)

- Input fluids temperature.

- Output fluids temperature.

- Fluids flows.

- BTU/h capacity.

- Equipment applications.

Industries

- Petrochemical industry

- Power industry

- Cooling and heating industries

- Marine industry

- Geothermal industry

- Plastics industry

- Metalworking industry

- Paper industry

- Automotive industry

- Aeronautics

Applications

- Heating/cooling of gaseous or liquid fluids.

- Boilers.

- White water heat recovery unit

- Evaporative condenser

- Evaporative cooler

- OFWF and ONWF transformer oil coolers

- Plastics injection

- Power plants

- Die-cutting

- Machine tooling