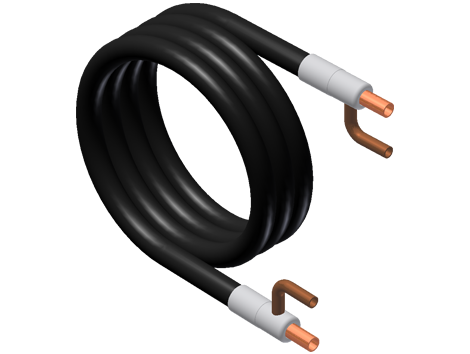

Coaxial Heat Exchangers

Coaxial exchangers are manufactured in an ISO 9001:2015 certified plant and are built to adapt to changes as these industries progress.

Applications:

-

Heat Pumps

These devices work efficiently as refrigerant condensers or evaporators by transferring heat with water. This makes them an ideal choice for both water source heat pumps (WSHP) and water-cooled condenser applications.

They feature Packless Green Surface technology to improve efficiency and energy savings. Standard sizes are available for systems from 1⁄2 to 30 tonnes.

-

Double wall

Specifically designed to remove heat from the overheated refrigerant discharge steam from air conditioning, cooling or heat pump systems in order to heat drinking water. Available from 1 to 3 tons.

The condenser uses a double-walled tube to ensure that the coolant does not mix with drinking water in the unlikely event of a refrigerant leak.

These exchangers are listed in C-UL-US for coolant-side working pressures of 650 psig and water-side working pressures of 500 psig.

-

Ice machines

A coaxial "tube-in-tube" design is used to provide efficient heat transfer and minimize fouling. These exchangers are listed in C-UL-US for coolant side working pressures of 650 psig and water side working pressures of 500 psig.

Available for machines producing from 150 to 1,800 pounds of ice per day.

The key to the high performance of the capacitors lies in the inner tube of multiple contoured conductors manufactured in a patented process. Turbulence imparted by circumvolutions to water and coolant flows further improves thermal performance while inhibiting the accumulation of deposits on surfaces.

The net result is a compact and effective heat exchanger with superior antifouling characteristics.

-

Chillers and evaporators

Available in seven standard sizes ranging from 1 to 5 tons capacity. The coil uses a coaxial "tube-in-tube" design that provides efficient heat transfer and minimizes fouling as a refrigerant cooler or evaporator.

These exchangers are listed in C-UL-US for coolant side working pressures of 650 psig and water side working pressures of 400 psig.

Optimal heat transfer is achieved with a backflow arrangement of water and coolant

-

Subcoolers

Available in seven standard sizes to offer a wide range of subcooler capacity options.

Available from 1 to 5 tons.

These exchanges are listed in C-UL-US for 650 psig coolant side working pressures and 400 psig water side working pressures.

-

Desuperheaters

Designed to remove heat from refrigerant discharge steam from air conditioning, cooling or heat pump systems in order to heat drinking water. Use a double-walled pipe to prevent coolant from mixing with drinking water in the unlikely event of a coolant leak.

These equipments are listed in C-UL-US for coolant-side working pressures of 650 psig and water-side working pressures of 500 psig.

Available from 4 to 15 tons.